Cell Line Development

Find the best host cell line for your biotherapeutic drug

Cell line development is a critical step in establishing a successful biopharmaceutical manufacturing process. From evaluating suitable DNA vector constructs to selecting the top production clones, a well-designed cell line development strategy is essential for achieving optimal GMP production solutions.

Reaching optimum productivity and bioactivity is challenging, as product quality attributes can vary significantly between different biotherapeutics. Given the variability in product quality attributes among different biotherapeutics, identifying the most suitable expression host is crucial for ensuring high-quality outcomes.

FyoniBio’s Mammalian Cell Line Development Services

At FyoniBio, we offer a unique portfolio of custom-tailored mammalian cell line development services that leverage our CHO and human versatile platforms and cell lines along with our process development expertise to deliver exceptional results. Our robust cell line portfolio includes:

CHO CLD Services

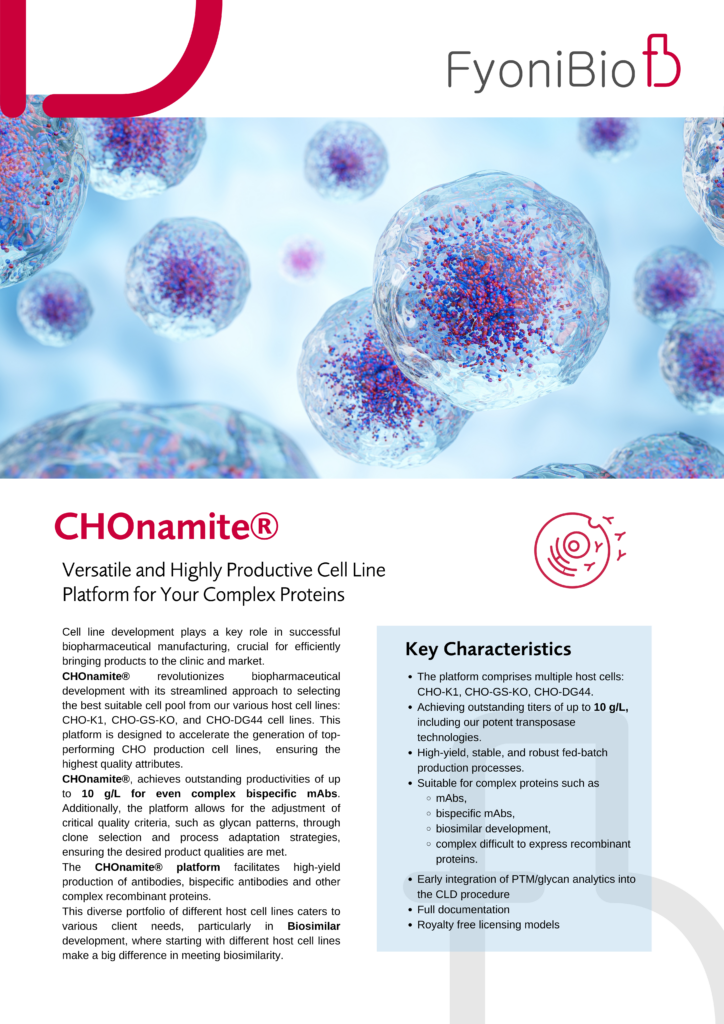

CHOnamite®: Based on classical CHO-K1, CHO-GS-KO, and CHO-DG44 cell lines, designed for high-yield production.

CHOFlow®: A glycoengineered CHO-K1 FUT8 knock out cell line technology for production of afucosylated monoclonal antibodies.

These cell lines enable high yield production of antibodies and other complex mammalian proteins. Moreover, this versatile portfolio of different cell lines offers our clients the best solution for biosimilar development.

Key Benefits:

- Broad capabilities: Expression of antibodies, bispecifics, biosimilars, and complex mammalian proteins.

- Exceptional productivity: Outstanding titers, e.g., > 12 g/L for monoclonal antibodies.

- Optimized processes: High-yield platform fed-batch processes.

- Customized glycan profiles: Opportunity to select between afucosylated mAbs in CHOFlow® or classical mAbs in CHOnamite®.

Learn more about the CHOnamite® platform and CHOFlow® cell line.

Human CLD Services

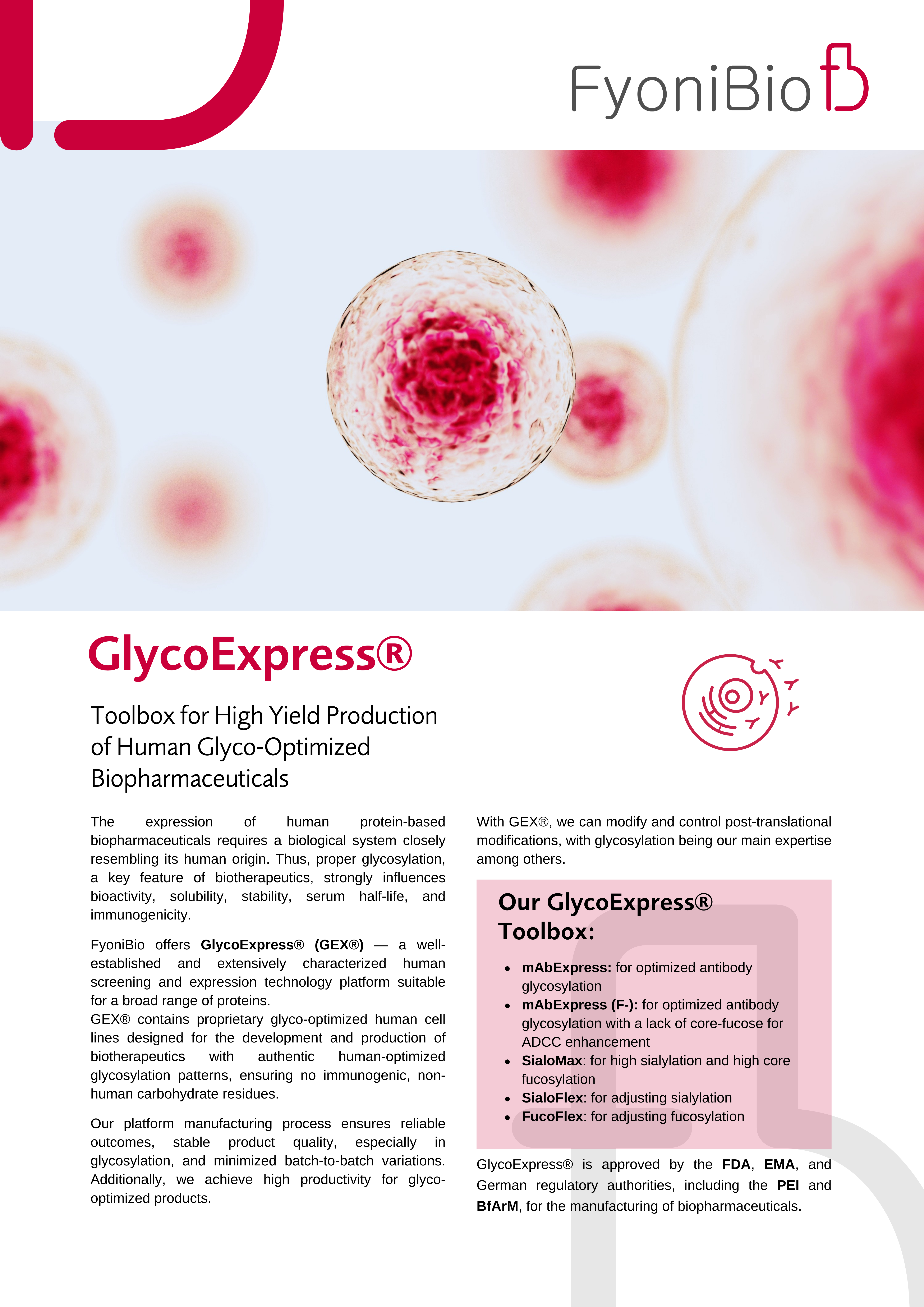

GlycoExpress® (GEX®) is a screening and high yield production platform featuring glyco-optimized human cell lines for the development and production of biotherapeutics with authentic human post-translational modifications (PTMs), such as glycosylation.

This platform supports the high-quality expression of difficult-to-express glycoproteins, ensuring superior product quality.

Key Benefits:

- Proven performance: Established expression platform for difficult-to-express, and complex glycoproteins.

- Authenticity and precision: Genuine human glycosylation and further PTM.

- High productivity for glyco-optimized products

- Customizable glycosylation: Toolbox of glycoengineered cell lines for adjusting sialylation, fucosylation, and mannose-6-phosphate.

Learn more about the GlycoExpress® platform for human cell line services.

Our state-of-the-art cell line development focuses on identifying highly productive cell clones with excellent quality parameters. We offer:

- Robust and Scalable Systems: Ensuring smooth tech transfer to the GMP manufacturer of your choice.

- Flexible Commercial Licensing: Providing royalty-free licensing models.

- Comprehensive Documentation: Fully traceable to fulfill EMA and FDA requirements.

FyoniBio also provides customized, fast-track, and cost-effective host cell line feasibility studies, through which you can compare your protein across our versatile cell line platforms, enhancing the efficiency and success of your biopharmaceutical development. Our advanced technologies and tailored approach maximize your product’s potential.

Fast Track Cell Line Development

Accelerating cell line development is key to a cost-efficient biopharmaceutical manufacturing process. At FyoniBio, we combine high-producing cell lines with customized expression vectors including a highly potent transposase technology. Our pool selection procedures increase the likelihood of identifying high producer clones. We integrate PTM/glycan analytics early in the process to verify protein quality, ensuring fast turnaround times.

The following infographic shows different steps performed during cell line development process:

Our development process includes:

- Single Cell Cloning: Using 3-4 highest producing pools to bring forth clones with varying characteristics.

- Multiple Rounds of Clone Screening: From initial 96-well screening to bioprocess-integrated screening in batch, fed-batch, and perfusion modes.

- Early USP Optimization and Stability Testing: Enabling direct transfer to a GMP manufacturer.

Need more information about our cell line development services?

We are happy to support you with your cell line development project! Share your questions and requests, and our scientific experts will respond promptly.

Frequently Asked Questions (FAQ) for Cell Line Development Services

Each project is unique, and we take this into account to tailor our services to your specific needs. At FyoniBio, every individual project is meticulously planned to align with the customer’s specifications, costs, and timelines. This is why the project plan, consisting of one or more work packages, is designed with flexibility in mind. It can be discussed and adapted as needed to ensure it meets your expectations. Get in touch with us and discuss the specific requirements of your project.

While CHO cells often demonstrate remarkable productivity, some proteins simply do not perform well in this rodent system. In such cases, we have shown that difficult-to-express proteins can be more effectively expressed in our human cell lines. Furthermore, with these human cell lines, your protein will carry exclusively fully human post-translational modifications. This is particularly advantageous for therapeutic applications, as it can reduce immunogenicity and enhance protein activity.

The capabilities of CHO cells range from high mannose structures to fucosylated complex N-glycan structures with multiple antennae. A notable characteristic of CHO cells is their high sialylation in an α2,3 linkage. In contrast, GEX® cells exhibit comparably lower levels of high mannose structures. Moreover, the capping of N-glycans with sialic acid can be fine-tuned by selecting a specific GEX® cell line, and process parameters during production can be adjusted to refine distinctive glycosylation characteristics.

A significant difference between the two cell lines is the unique ability of GEX® cells to produce N-glycans with bisecting GlcNAc, which plays a critical role in the efficiency of mAbs. While sialic acids in CHO-derived material are exclusively linked in the α2,3 conformation, GEX® cells can produce both fully human α2,3 and α2,6 linkages. Additionally, CHO-derived material contains both NeuAc and NeuGc, whereas GEX® cells produce only NeuAc.

The capability of CHO cells ranges from high mannose structures to fucosylated complex N-glycan structures with up to multiple antennae. A general characteristic is a high sialylation in α2,3 linkage. For GEX® cells comparably lower amounts of high mannose are observed. The capping of N-glycans with sialic acid can be adjusted by selecting a different GEX® cell line. Additionally, process parameters during production are fully adjustable to meet specific needs. For the CHOnamite® and GEX® platforms, an RCB can typically be obtained after 16 or 20 weeks, respectively. However, depending on the customer’s requirements for clonality, a second cloning round may be necessary, which adds an additional 6–8 weeks to the timeline.

Cell Line Development Services – Related Content

Learn more about the CHOnamite® platform and CHOFlow® cell line.

Learn more about the GlycoExpress® platform for human cell line services.

Explore how the potential of your biotherapeutic can be evaluated across multiple cell line platforms in our customized feasibility study.